Thermic Boiler Manufacturer in Chennai – Efficient and Reliable Heating for Industrial Use

Looking for a top-notch thermic boiler manufacturer in Chennai? Look no further than JP Boilers! With years of experience and expertise in the industry, JP Boilers has established itself as a leading manufacturer of thermic boilers in Chennai. Their commitment to quality and innovation, coupled with their customer-centric approach, has made them a trusted choice among businesses and industries in the city. In this blog post, we will dive into the world of thermic boilers and explore why JP Boilers is the go-to choose for all your boiler needs in Chennai. So, let’s get started!

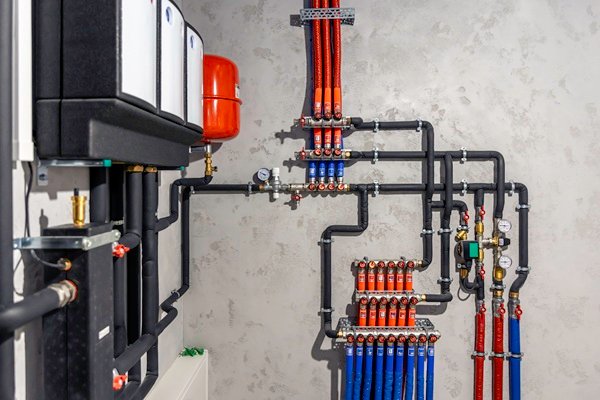

In industries where high-temperature heat is needed without using steam, Thermic Boilers also known as Thermic Fluid Heaters are the best choice. These advanced heating systems offer consistent, efficient, and safe heating for a wide range of industrial processes. If you’re searching for a trusted Thermic Boiler Manufacturer in India, it’s important to understand the product features, uses, and how it benefits your operations

What is a Thermic Boiler?

Thermic Boiler transfers heat using a thermic fluid instead of water or steam. The fluid circulates in a closed-loop system, providing uniform and controlled heating without the pressure-related risks of steam boilers. This makes thermic boilers a safe and cost-effective heating solution for industries that require continuous heat at high temperatures.

Product Specification:

- Type: Coil Type / Shell and Tube Type Thermic Boilers

- Capacity: From 0.1 million kcal/hr to 10 million kcal/hr

- Working Pressure: Operates at atmospheric pressure (low-pressure system)

- Fuel Options:

- Diesel

- Furnace Oil

- LPG / Natural Gas

- Coal

- Biomass / Wood

- Husk & Agro-waste

This flexibility in fuel usage allows industries to choose based on availability and cost-efficiency.

Applications

Thermic boilers are widely used in sectors that need consistent heating over long periods. Some key industries include:

- Food Processing Units – oil heating, frying, drying

- Textile Manufacturing – drying, dyeing, and heating

- Pharmaceuticals – chemical mixing and drying

- Chemical Industries – reactors, jacketed vessels

- Printing & Packaging – lamination, drying inks

- Rubber & Plastic – mould heating, extruders

- Oil Refineries – heating oil and related fluids

These boilers are often used in drying chambers, heat exchangers, and process heating systems

Benefits of Thermic Boilers:

Thermic boilers are popular in the industrial sector due to their unique advantages:

- High Temperature at Low Pressure: Safe and reliable operation

- Fuel Flexibility: Operates with gas, oil, biomass, or coal

- Cost-Effective: High thermal efficiency reduces energy costs

- Low Maintenance: Fewer moving parts and corrosion-resistant designs

- Quick Startup: Heats up quickly, saving valuable production time

- Compact Design: Easy to install and space-saving

Why Choose a Trusted Thermic Boiler Manufacturer in Chennai?

Working with an experienced manufacturer ensures:

- Customized Design tailored to your industry and application

- Use of Quality Materials for long-lasting performance

- Advanced Safety Features for smooth operation

- Compliance with IBR Standards for peace of mind

- Expert Technical Support and post-installation assistance

Thermic Boiler Overview

Feature Details

Capacity 0.1 – 10 million kcal/hr

Pressure Low (atmospheric)

Fuel Types Diesel, Gas, Coal, Biomass, etc.

Common Industries Food, Pharma, Textile, Chemicals

Get in Touch

Looking for the best Thermic Boiler Manufacturer in Chennai? Connect with us today to get a free consultation and explore our range of energy-efficient thermal heating solutions!

Get a Free Consultation

Looking for the best Thermic Boiler Manufacturer in Chennai? We offer energy-efficient, custom-built thermic fluid heaters designed for your industry. Whether you need a small-capacity unit or a large-scale heating system, we’re here to help.

Contact us today to schedule a free consultation and receive a quote. Let us help you improve your production process with reliable and safe heating technology!