Coal Fired IBR Steam boiler in Chennai

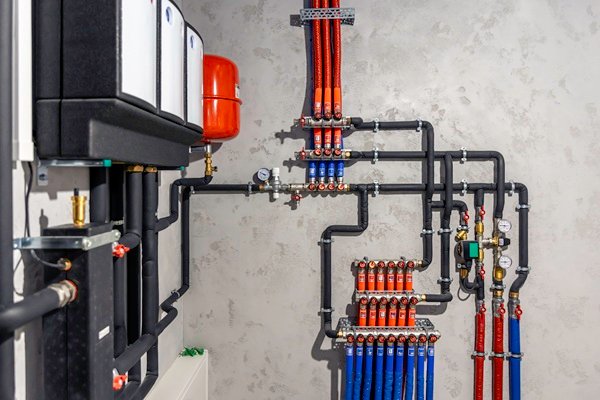

Coal Fired IBR Steam Boiler in Chennai – High-Efficiency Steam Generation for Industries Are you looking for a cost-effective and high-performance steam boiler for your factory or industrial unit? A Coal Fired IBR Steam Boiler in chennai might be the perfect solution. These boilers are built to handle large steam demands while keeping operational costs low. Let’s explore what makes coal-fired IBR boilers a great investment for industrial heating. What is an IBR Steam Boiler? IBR stands for Indian Boiler Regulations. It ensures that the boiler is designed and manufactured following safety and quality standards. An IBR Steam Boiler is approved by the government and suitable for use in industrial applications that demand consistent and powerful steam generation. Product Overview: Coal Fired IBR Steam Boiler Here are the technical and performance specifications of a typical coal-fired IBR boiler: Feature Details Type Horizontal / Vertical Shell Type Boilers Capacity Range 500 kg/hr to 10,000 kg/hr Working Pressure 10.54 kg/cm² to 21 kg/cm² Fuel Used Bituminous coal, lignite, or anthracite Efficiency Up to 80% with proper combustion systems Construction Fire-tube or Water-tube design The use of coal as the primary fuel helps in reducing fuel costs and ensuring long operating cycles. Common Applications Coal fired IBR steam boiler in chennai are commonly used in the following industries: Food & Beverage Industry – for sterilization, cooking, and drying Textile Industry – for dyeing, washing, and drying fabrics Chemical Industry – for heating reactors and mixing tanks Paper Mills – for pulp cooking and drying Pharmaceuticals – for sterilization and process steam Steel & Iron Plants – for steam heating and power generation Benefits of Coal Fired IBR Steam Boiler in Chennai Cost-Effective FuelCoal is cheaper and readily available in many regions, making it ideal for long-term use. High Steam OutputSuitable for heavy-duty industrial applications with large steam demand. IBR CertifiedBuilt according to government safety regulations, ensuring long life and low risk. Durable and Long-LastingStrong construction materials provide resistance to high pressure and temperature. Energy-Efficient DesignsAdvanced combustion techniques improve fuel-to-steam efficiency. Product Highlights (use this table visually on your website) Category Details Capacity 500 kg/hr to 10,000 kg/hr Operating Pressure 10.54 to 21 kg/cm² Fuel Coal (bituminous, lignite, anthracite) Applications Food, Textile, Pharma, Chemicals, Steel Boiler Type Horizontal Shell or Water-tube Why Choose Us as Your IBR Steam Boiler ? We are one of the leading Coal Fired IBR Steam Boiler in Chennai, offering: Custom-built boiler systems based on your plant’s requirements BR-compliant designs with all safety valves and accessories On-site installation and maintenance support High-efficiency combustion systems for better fuel usage Quick delivery and responsive after-sales service Talk to Our Experts Today If you’re planning to install a Coal Fired IBR Steam Boiler in chennai your factory, don’t delay. We’ll guide you with the right boiler model, capacity, and setup plan that fits your business. Whether you’re a small-scale industry or a large manufacturing plant, we offer solutions that improve productivity and reduce operating costs. Get in touch with our team today for a free consultation and quote!s

Coal Fired IBR Steam boiler in Chennai Read More »